At TaylorMade's global media launch for the M1 'unmetalwood' family and the PSi irons, I caught up with Chief Technical Officer Benoit Vincent to find out more about the design strategy behind the new clubs.

Hi Benoit. The M1 Driver is a multi-material club and it is the first one you have really done, even though carbon has been around for quite a while. Why have you chosen to use it now, or perhaps why have you not used it in the past?

I think that we have been so good at making products with titanium and so good at processing titanium that the available composite materials were never good enough to challenge what we were doing in titanium. We have tried it many times over the last 20 years, I can’t remember one year where we didn't try, but every year titanium won.

I think the reason for that is twofold: partly because we are really good at processing titanium and partly because our development in composite products was not as good as our progress in titanium.

We studied composite to put it in the face of the driver, but the face of the driver is the most complicated part of the driver because it has to withstand such an impact with tremendous loads so composite is not made to be impacted directly.

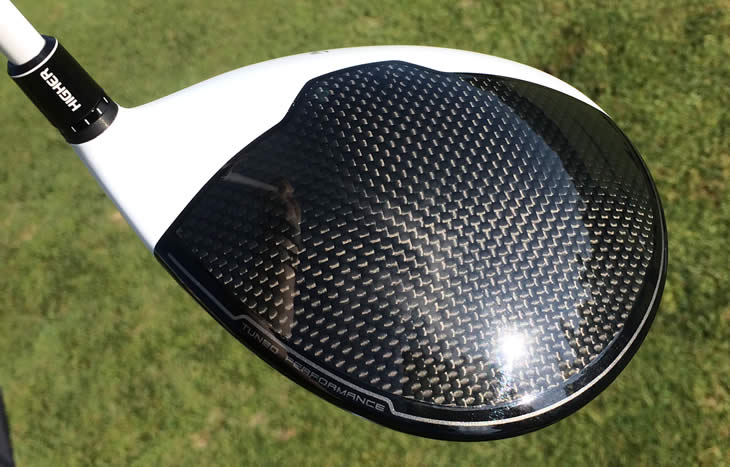

For example a golf shaft is made from composite materials and is used in golf clubs but it is not impacted. We made enormous progress in studying composite materials for use in the face and we used that knowledge to make a high performing crown made from composite material and that is where we passed what we were able to do with titanium on its own.

With the R15 and some of the previous drivers you put great emphasis on a low and forward centre of gravity. With the M1 there is still the element of the forward CG, but you seem to have given people the option of moving it back. Is this a change in philosophy or just an evolution?

I think there are two different components. What really matters for us is to give a hot trajectory driver, which is low spin, high launch and high ball speed. In order to get those highs we needed to ensure that the projection of the centre of gravity was in the middle of the face. You can do that in a number of ways and one way is to move the weight low and forward which we have done in products in the past.

What we have been able to do with the M1 driver is use the lightness of the composite crown to allow us to move weight from the top of the club to the bottom, dropping the CG even lower than in previous models and allowing us to give the option of moving the weight further back without impacting on the projection of the centre of gravity to the centre of the face.

With the SLDR there was one weight in the track and this changed to two weights in the R15 and now back to one with the M1 Driver. Why is that?

The main purpose of the front weight track is to allow the movement of weight from left to right, so you can use two weights, but fundamentally you only need one weight that can go to the left or it can go to the right. In the R15 driver we included two weights to bring in the ability to adjust inertia, in that you could split the two weights to either end of the track to make the club more stable and forgiving. But it was forgiveness without a centre of gravity adjustment, so you had to choose between that or adjusting the weight to the left or to the right.

What we are doing with the M1 driver is delivering the ability to adjust forgiveness with the weight on the back track so we don’t need to include that as an option that actually limited the performance of the front weight.

The M1 Driver comes in a 460cc head and a 430cc head. Is there a reason you have the smaller head? I know it is lower spinning, but would you not be able to achieve the lower spin by adjusting the weights on the larger head?

All of the efforts have been into saving weight. On the crown for example substituting the 22g of titanium with 10g of Carbon Composite saved 12g and then after gluing them together we saved 5 to 6g. So it is those precious 5 to 6g that we use on the sole plate to create all of the adjustment options. Imagine all the work that went into saving that weight and how hard it would be to save another 5g.

One of the easiest ways to do that is by shrinking the size so by going from 460cc to 430cc there was an immediate gain of 5g that we could use to locate the weight even further down, so that is why we have also offered a 430cc head and it is us experimenting with what is possible moving weight even lower.

But of course not everybody could play the 430 because it is a smaller head with less stability, so it is made for better players who can cope with that and have the skills to cope with the even lower spinning profile of the product created by moving the additional weight.

The M1 Fairway has gone the other way in terms of the sliding with two weights in the track. Is this now a stability feature rather than a left to right feature?

Firstly there is now a lot of weight we have to accommodate in the front track thanks to the saving we have made from the multi material crown. We now have 30g of weight rather than 25g so it is a lot of weight and therefore firstly in practical terms it is easier to split them into two weights of 15g in order to keep them in securely in the cavity because all those weights want to do is one thing and that is to fly out of the cavity! By splitting the weights it is easier to control them in that manner.

Secondly, fairway products are smaller products so therefore there inertia is smaller and therefore you give players the option to increase the stability and forgiveness by splitting the two weights if they want to.

Would you say it is a little more forgiving than the R15 fairway?

Yes, if you split the two weights it will be more forgiving than the R15 fairway, but is also lower spinning with faster ball speed than the R15 thanks to moving the weight from the crown down to the bottom of the club.

The M1 driver and the M1 fairway have the Carbon Composite crown, but the M1 Rescue is all steel and has two sole weights, one quite heavy at 25g, and it looks different being all black. Why have you chosen this route for the Rescue?

What we are trying to accomplish with the M1 Rescue is a little different to the challenges we faced with the M1 driver and the M1 fairway. All of the Tour players we have spoken to who have tested a Rescue or have tried a Rescue in the last 15 years have said the same thing and that is that they don’t want to draw or hook their Rescue, they just want something that goes straight or with a slight fade, removing the problem of hooking their Rescue.

With this club, that is the challenge that we faced and have been trying to solve. We have done that for Tour players previously by creating prototypes where all of the weight goes on the toe, but we have never released those to the public as they are too challenging to be played by most golfers.

So we have said OK, how can we provide a product that is good for the best players who want it all toe weighted, but that will also work for the majority of all golfers. That is how we came up with the moveable weight system for the M1 Rescue. In fact the only other Rescue we’ve made was our first one back in 2006, so it is the first time in 10 years we have gone back to this system in order to solve the problem.

We’ve been able to do this thanks to the design of the weights that are really flush to the sole so don’t provide any interference at impact and also keep spin low, so in the M1 we have what we think is the real application of moveable weight in a Rescue club.

So would you say the Rescue is more suitable for slightly better players than the M1 driver and fairways, as it is seems through the set up and all black looks to be addressing a slightly different market?

In terms of looks we were trying to be a bit more versatile on the Rescue product and aim it towards players who want a more traditional look. When we looked down at the Rescue the crown is smaller so we didn’t think it was possible to accommodate a feature similar to that of the driver and fairway crown on the Rescue club.

Moving on to the PSi irons it seems that RSi 1 irons have been a big success and the RSi 2 and RSi TP iron technology has been moved into these PSi irons. What has been improved from those two previous irons to the PSi?

The first thing with the PSi irons is that they have been made for better players. So we are targeting with this iron single digit handicap players. In order to do that we really had to stick to a thin top line, thin sole plate, a shorter blade length and a smaller offset, the things that really appeal to a better player.

When you do that and you are trying to introduce some of the performance benefits of the technology we introduced on the RSi product, it is a big challenge because you don’t really have the space or the room to implement all of that.

Trying to introduce not only a players' package, but also the consistency of performance across the face that comes from the face slots as well as the increased ball speed on the low face shots together is often detrimental to the product as a whole.

So in the PSi irons the way we solved that problem is by introducing the undercut 360 cavity to deliver consistency and distance as well as a specific device to control the sound. The Dynamic Feel System comprises a compression damper located in the back and bottom of the product and a three layer badge that is glued on the back of the face and controls the sensation.

Now we really have a package for a better player, the technology for consistency of distance and also the damping system to deliver the feel that is expected by the best players.

One thing I noticed in the RSi and the PSi is that there is a lot of change in materials as you go through the set. The 4 and 5 iron have a tungsten toe weight, then the speed pocket goes up to the 7 iron and face slots go up to the 8 iron and from there we move into forged irons. Why have you done that rather than try to make them all forged or all cast?

What we have tried to do is design every single iron to be the best that we can deliver. So we want the 3, 4 and 5 irons to be long and consistently long because that is what matters in those products. And when we come to the short irons, the 8, 9 and wedge, we want them to feel good and be a touch product for the approach game so that is why we went to forged for those clubs.

We are trying to find construction and materials that are really best suited for the irons in the set rather than be stuck dogmatically into one construction for the sake of the construction, to maximise the performance of every single iron in the set.

Have you had to manage the ball speeds off the face as I’d imagine a cast face and the flexing it would allow would give faster ball speeds than a forged face that has less flex. Has that been an issue and how have you managed to get around it?

It is true that the forged face because it is thicker is going to be slower than the thinner cast face. So what we did on the PSi Tour irons is introduce some of the technology we used in the PSi iron such as the slots on the face and the sole, except they are not as effective as they are on the PSi iron, which makes it an improvement over a truly forged iron, but not as much of a benefit as you’d find in the PSi, so it is in-between.

How do you manage that transition in the PSi irons, where the sole and face slots stop being used and then the shorter irons are also forged, rather than the whole set being forged?

What we see is that the benefits of casting is helping us put distance into the clubs because we can make the face way thinner and way more active so it is more interesting to do that up to the 7 iron. When it comes to the 8, 9 and PW you still need to be able to play golf. We don’t want the PW to go 200 yards, so we are actually trying to get standards on our short irons to make them respect a certain distance and that is where we need less technology on those products than we need on the longer irons where we are looking for distance.

Speaking of managing the distance I noticed that on everything except the 3 iron all the clubs are have lofts of half degrees, for instance the 6 iron is 27.5° and the 7 iron is 31.5°. Is there any reason for having these half degree lofts?

You know, when you dial half a degree you are generating about half of that in launch angle so what I am saying is that a degree of loft is changing the trajectory by half a degree. So to deliver the distances and trajectory that we desire we had to go to the extreme level of detail in every aspect of the product to get the perfect gap between irons and if we needed half a degree to do that then guess what - we are going to do that.

More from TaylorMade